A New Printing Dimension of Printing

- 2013-11-15

Printing process steps into 3D world ... fascinating but not so green?

Would it be weird if one day we can literally "print" an edible pizza, a usable car or even a living kidney? Probably, but these are the goals that technology experts around the world aim to achieve through 3D printing.

Also known as Rapid Prototyping, 3D printing creates stereoscopic product by successively "printing" thin layers of an ultraviolet curable material one on top of the other. It is said to be a greener solution for manufacturing industry by using recyclable feedstock and reducing the consumption of raw materials.

The new printing technology has even triggered government's interest. The U.S. space agency, National Aeronautics and Space Administration, plans to have its first 3D printer in space station in 2014. As astronauts cannot nip out to shop for components while they are in the orbit, 3D printer allows them to print what they need which saves cost for resupply missions.

While space exploration may be too far from Hong Kongers, some local designers have embraced 3D printing. Yet, is this technology taking steps to the road of green manufacturing in the city?

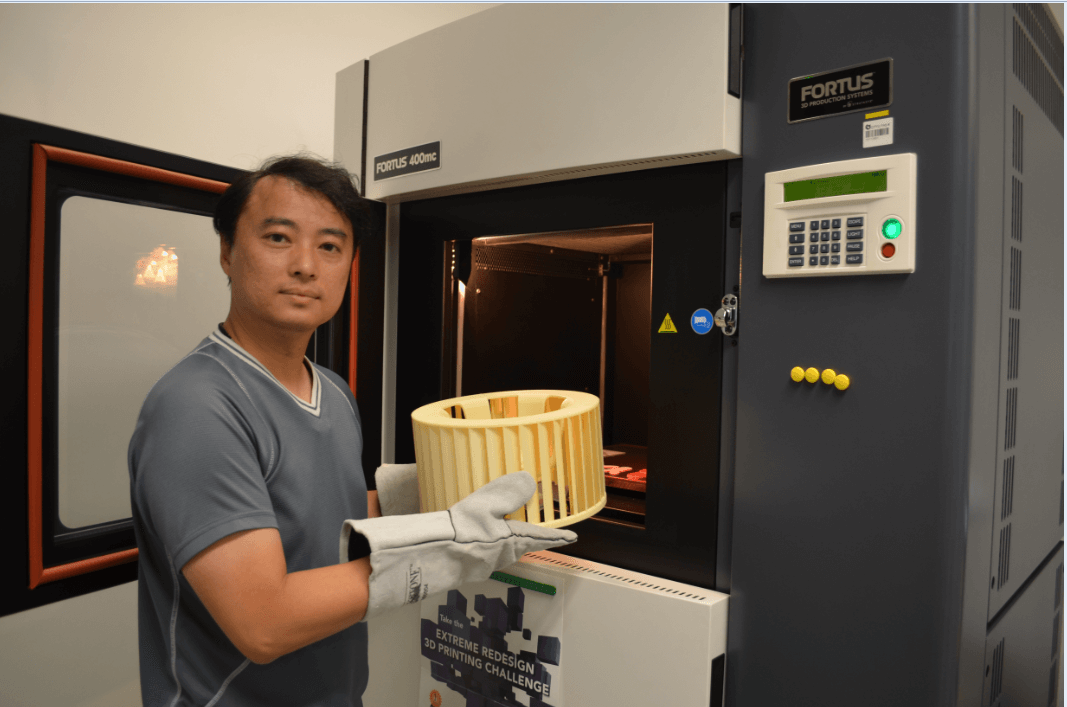

Mr Frankie Fan, the Executive Officer supervising the use of 3D printer in laboratory at City University of Hong Kong.

"3D printing abandons the traditional way of making a figure by cutting and attaching parts," he said. "It is an adaptive manufacturing in which no mold is needed during production."

He said 3D printing also reduces carbon emission by minimizing transportation of goods. "Instead of shipping the products, designers can send the graphics to buyers through the Internet, and let them print the goods on location."

Last September, a sculpture of Hong Kong pop singer in scale of 200% was displayed at the local first-ever 3D scan and print exhibition.

Mr Lam Shu-kam, creative director of the company that organized the exhibition, said the rapid prototyping technology helps make the figure more detailed. He would scan the individual and confirm all the details in computer before printing.

Appealing as the new printing technology may sound, the technology comes with downsides.

Mr Fan said, University students mainly use three types of raw plastics to make figures, but only one of them, extracted from cornstarch, is bio-degradable.

"Plastics and metals used as feedstock for 3D printing are similar to those of traditional manufacturing in Hong Kong," he said, "pollution can be equally harmful."

Mr Wong Wing-fai, head of Rapid Prototyping and Manufacturing Unit of Industrial Centre at the Hong Kong Polytechnic University, said the technology is still in its initial stage and can only applied locally for educational purpose rather than industrial one.

"Whether the technology is eco-friendly differs in terms of how we use it and what material we use during printing." said Mr Wong, who has experience of making bio-medical models and metal plating by rapid prototyping.

For example, more non-degradable materials are used for printing a car, more pollution there will be. Also, more fuels will be needed for driving the model.

Besides, desktop 3D printers designed for small-scaled manufacturing, are classified as "high emitters" of ultrafine particles when melting the plastic feedstock. A report published by researchers from the US Illinois Institute of Technology says, "every minute during operation a printer emits billions of particles invisible to human eye.

The particles may pollute the indoor air and cause serious respiratory disease for human in long term".

It suggests that a standalone 3D printer should be equipped with good filtering and ventilation systems.

"Printers using powder feedstock instead of plastic may also result in high emission of particles. Users have to wear masks specialized to filter small particles to avoid inhaling the harmful substance." said Mr Wong.

Despite all these challenges, he is optimistic about the future of 3D printing.

"To unleash 3D printing's potential as a greener manufacturing technology, the key will be to create unique, greener product life cycles," said Mr Wong. "With further improvement, it holds the hope of a manufacturing and innovation revolution."

Reported by Vicky Wan

《The Young Reporter》

The Young Reporter (TYR) started as a newspaper in 1969. Today, it is published across multiple media platforms and updated constantly to bring the latest news and analyses to its readers.

The man behind the mask

[SOPA Series -Thomas Fuller]An eye-opening assassination

Comments